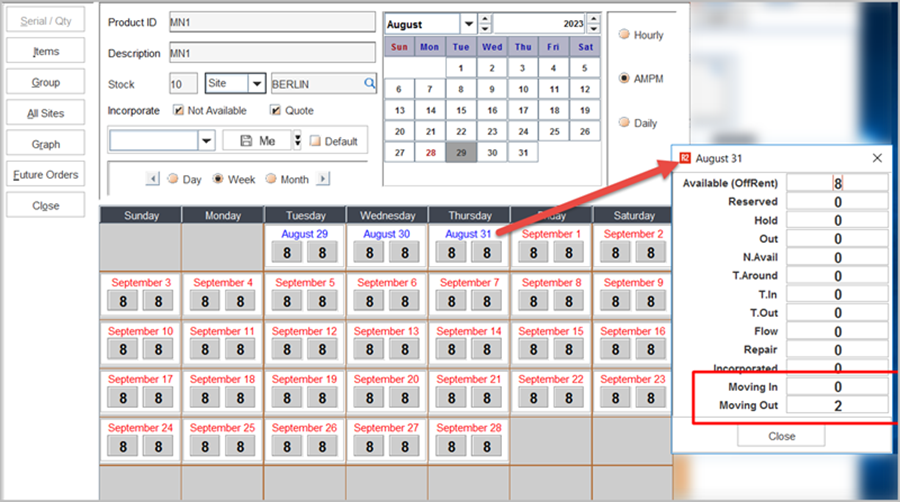

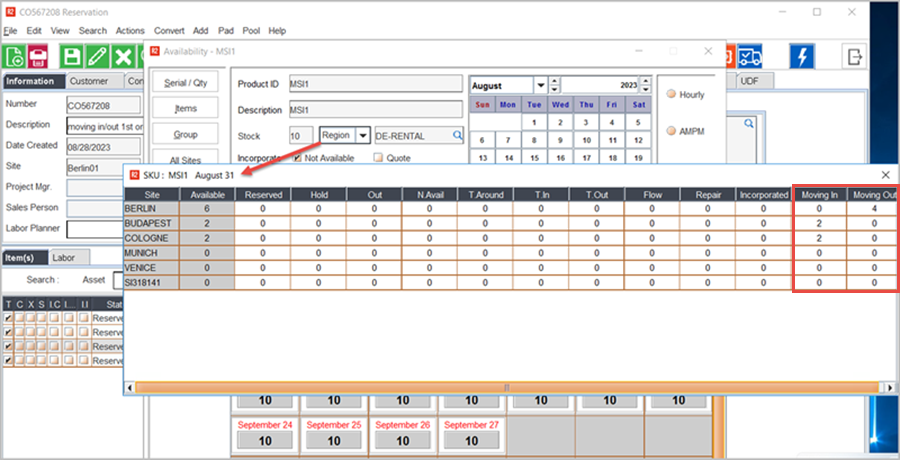

The Moving In and Moving Out values will show only until the line is Returned similar to how T.In & T.Out are shown until receive and after that it will be removed

Content was last updated in 06.23.09-00

In Availability Calendar drill down there are two new entries as Moving In and Moving Out This will be available in Site Availability / Sub-region Availability / Region / All Sites Availability / Group Availability - drill down windows. These two fields will show values when there are any item on a Order is planned to be returned to a different Site (Returning Site) than the Shipping Site. This help you to check, how and why the availability has changed in a specific Site/Region/Sub-region.

|

The Moving In and Moving Out values will show only until the line is Returned similar to how T.In & T.Out are shown until receive and after that it will be removed |

The possibility of having Returning Site different from Shipping Site in R2 is when the following flags are enabled in Configuration.

Equipment Pooling enabled

Enable Order Shipping Site and Returning Site

Sample workflow showing how availability changes in different sites according to reservation status.

Site A stock has 10 units of Items in stock.

Site B stock has 0 units of Items in stock.

An Item gets Reserved in Site A then Reserved shows 1 until item is returned to Site B.

Available quantity decreases to 9, to show how the quantity changes to 9 in Site A the 'Moving Out' is shown with reserved quantity 1.

Now In Site B the Available quantity shown as 1, to know how quantity in Returning Site changed to 1 'Moving In' is shown with received quantity 1.

Calendar dates |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Customer Order Line is Reserved/Out |

Ship From Site A |

Returning To Site B |

||||||||||||||

Site A |

Avail |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

Reserved/Out |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

|

||||||||||||||||

Site B |

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Reserved/Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

When Customer order line is returned,

The Available quantity in Site A shows 8, the Site A has sent out one item to Site B so Out is shown as 1.

The Site B has 1 Available Item.

Calendar dates |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Customer Order Line is Returned |

Ship From Site A |

Returning To Site B |

||||||||||||||

Site A |

Avail |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Out |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

|

||||||||||||||||

Site B |

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Consider This:

Site A has Stock Quantity = 0

Site B has Stock Quantity = 0

Site C has Stock Quantity =10

When Order gets Reserved in Site A with quantity 1

The Reserved shows 1, 'Moving Out' shows 1 until item gets returned to Site B, and 'Moving In' shows 1 in returning Site B until Item is received.

The Site B now have 1 Available quantity, to know how the quantity is 1 the 'Moving In' is shown with received quantity.

But, how did the Site B receive the item from Site A if stock in Site A is 0?

The Site A, B and C are related to same Sub-Region so Pooling is enabled for these Sites and Site A, Site C has Ops line reserved.

When it is a Ops order the Site A receives Items from Site C and sends it to Site B.

Site C has 10 items Available in the stock, Reserved items is 1 at Site C and Site A, so the Availability becomes 9 at Site C, to know how item gets reduced to 9 the 'Moving Out' is shown as 1 until Site B receives item.

| Calendar dates | 29 |

30 |

31 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Customer order line is Reserved | Ship From Site A |

|

Return To Site B |

|

||||||||||||||

| Pool Ops line is Reserved/Out | Ship from C |

Return to A |

||||||||||||||||

| Site A |

|

|||||||||||||||||

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving Out |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Reserved/Out |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| Site B |

|

|||||||||||||||||

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Reserved/Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| Site C |

|

|||||||||||||||||

Avail |

10 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving Out |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Reserved/Out |

0 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

When Order gets Reserved at Site C and Site A, The Reserved shows 1,Items sent from Site C to A and Site A re sent items to B, to know how Site B has 1 quantity available the 'Move Out' is shown with quantity sent.

At Site B Available quantity is 1 and 'Moving In' shows 1 quantity.

Now at Site C and Site A from date items sent the Available quantity shows 8, because the 1 item sent to Site B, so Out is shown as 1.

| Calendar dates | 29 |

30 |

31 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Customer order line is Reserved | Ship From Site A |

Return To Site B |

||||||||||||||||

| Pool Ops line is Received | Ship from C |

Return to A |

||||||||||||||||

| Site A | ||||||||||||||||||

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Reserved/Out |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| Site B |

|

|||||||||||||||||

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Reserved/Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| Site C |

|

|||||||||||||||||

Avail |

10 |

8 |

8 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

0 |

0 |

0 |

0 |

0 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Reserved/Out |

0 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Now Items in Site A Availability is shown as -1, that is because, 1 quantity is taken from Site C and sent it to Site B, so Site A is left with -1items.

Site B has received 1 item Available in the stock is 1.

| Calendar dates | 29 |

30 |

31 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Customer order line is Returned | Ship From Site A |

Return To Site B |

||||||||||||||||

| Pool Ops line is Received | Ship from C |

Return to A |

||||||||||||||||

| Site A | ||||||||||||||||||

Avail |

0 |

0 |

0 |

-1 |

-1 |

-1 |

-1 |

-1 |

-1 |

-1 |

-1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Reserved/Out |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| Site B |

|

|||||||||||||||||

Avail |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Reserved/Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| Site C |

|

|||||||||||||||||

Avail |

10 |

8 |

8 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

Moving In |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Moving Out |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Reserved/Out |

0 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

When the Order line is Returned, the Moving In and Moving Out values will be reduced by the number of quantities returned as the stock gets moved to the receiving site permanently. |